As preparation I constructed a stem section from cheap material to find out the hidden secrets of getting it into proper shape. That helped keeping the waste of expensive Sapelli plywood (marine grade!) to an acceptable limit.

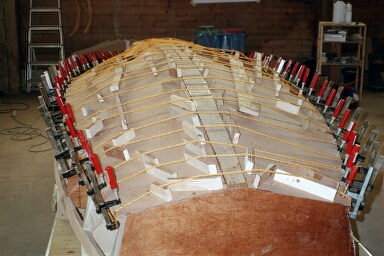

Next the planks were glued to correct length. I used two layers of 4mm to reduce the tension in the stem section. I cannot imagine I would have been able to bend a single plank of 8mm.

The first layer is glued and fixed using the staple gun. For the second layer, however I had to ...

... change my strategy.

I then discovered two spots where the second layer was not full-surface glued, so I drilled a small hole into the top layer, injected epoxy resin using a one-way syringe, covered the hole with tape, pressed, done!

Do it all again with the side sections, and ...

... there we go!

The joints between keel and planks were filled with thicked epoxy, and the whole body was coated with two layers of epoxy resin.

Two layers of LPU primer and three layers of LPU yacht paint finished the hull below CWL.